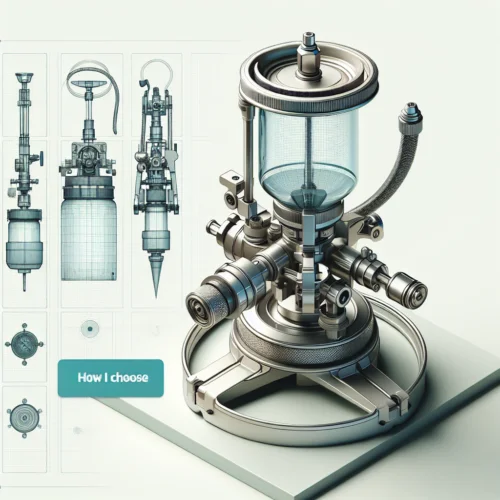

Looking to invest in a sprayer but feeling overwhelmed by the countless options available? Look no further! In this article, we will guide you through the process of choosing a sprayer, ensuring that you make an informed decision that meets your specific needs. Whether you’re a seasoned professional or a novice, we’ve got you covered. With our expert advice and practical tips, you’ll be equipped with the knowledge necessary to select the perfect sprayer for all your spraying needs. Say goodbye to confusion and hello to confidence as we embark on this sprayer selection journey together.

How Do I Choose A Sprayer?

Table of Contents

Understanding Different Types of Sprayers

Airless Sprayers

Airless sprayers are a popular choice for many DIY enthusiasts and professionals alike. These sprayers work by using a piston or motor to generate high pressure, which forces the paint or other material through a small orifice in the spray tip. The result is a fine mist that evenly coats the surface being sprayed. Airless sprayers are known for their speed and efficiency, making them ideal for large-scale projects.

HVLP (High Volume Low Pressure)

HVLP sprayers, on the other hand, operate at a lower pressure compared to airless sprayers. They atomize the paint using a high volume of air and produce a soft spray pattern. HVLP sprayers are excellent for achieving a smooth, professional finish, making them popular in the automotive and woodworking industries. They also minimize overspray, resulting in less wasted material and a cleaner work environment.

Air Assisted Airless Sprayers

Air assisted airless sprayers combine the best features of airless and HVLP sprayers. These sprayers use a combination of high pressure and high volume of air to atomize the material. Air assisted airless sprayers are versatile, allowing users to adjust the air pressure and volume to achieve the desired finish. They are especially useful for projects that require fine control over the spray pattern, such as furniture refinishing or cabinet painting.

Conventional (Compressed Air) Sprayers

Conventional sprayers, also known as compressed air sprayers, have been around for a long time and are still widely used today. They operate by using compressed air to atomize the paint or material. Conventional sprayers are suitable for smaller projects and touch-ups, but they tend to have more overspray compared to airless or HVLP sprayers. They are affordable and easy to use, making them a popular choice for beginners or occasional users.

Consider Your Project Needs

The type of material you will be spraying

Before choosing a sprayer, it’s essential to consider the type of material you’ll be spraying. Different sprayers are designed to handle different materials, such as latex paint, stain, varnish, or lacquer. Make sure the sprayer you choose is compatible with the material you intend to use to achieve the best results.

The scale of your job

The size of your project plays a significant role in selecting the right sprayer. For large-scale projects like painting the exterior of a house or a large warehouse, an airless sprayer would be the most efficient choice. On the other hand, smaller projects or intricate surfaces may require the precision and control of an HVLP or air assisted airless sprayer.

The spraying result you wish to achieve

Consider the finish you want to achieve with your sprayer. If you’re aiming for a smooth, professional-looking finish, an HVLP sprayer would be a suitable choice. If you prefer a textured or thicker coat, an airless sprayer might be more appropriate. Understanding the desired spraying result will help you narrow down your options and select the sprayer that best suits your needs.

Required preparation and clean-up time

Different sprayers have varying preparation and clean-up requirements. Airless and air assisted airless sprayers typically require more extensive preparation, like masking off surrounding areas and protecting furniture, as they tend to produce more overspray. HVLP sprayers, on the other hand, have minimal overspray and are generally easier to clean up after use. Consider the time and effort you are willing to invest in preparation and clean-up before making your final decision.

Factors to Consider When Choosing a Sprayer

Volume

The volume of a sprayer refers to the amount of material it can hold and spray. Larger projects typically require sprayers with higher volume capacities to avoid frequent refilling. Consider the size of your project and choose a sprayer with a volume capacity that suits your needs.

Pressure

Pressure is a crucial factor in spraying because it affects the atomization and coverage of the material. Higher pressure sprayers are better suited for projects that require faster application or thicker coatings. Lower pressure sprayers, like HVLP, are ideal for achieving a smoother finish with minimal overspray. Consider your project requirements and select a sprayer with the appropriate pressure range.

Proper tip size for the material you’ll be spraying

The tip size of a sprayer determines the spray pattern and flow rate. It’s important to choose the proper tip size for the material you’ll be spraying. Different materials require different tip sizes for optimal coverage and atomization. Refer to the manufacturer’s guidelines or consult with a professional to determine the correct tip size for your specific material.

Ease of maintenance and repair

When choosing a sprayer, it’s important to consider the ease of maintenance and repair. Look for sprayers that are designed with user-friendly features, such as easily removable parts and accessible filters. Additionally, check if replacement parts are readily available in case of any repairs. Choosing a sprayer that is easy to maintain and repair will ensure that your investment lasts for years to come.

Safety Measures With Sprayers

Operator safety

Sprayers can pose certain risks to the operator if not used correctly. It’s crucial to follow proper safety precautions, such as wearing protective clothing, gloves, goggles, and respirators. Ensure sufficient ventilation in the workspace to prevent the build-up of fumes. Familiarize yourself with the specific safety guidelines outlined by the sprayer manufacturer to protect yourself during use.

Handling and disposal of materials

Safety extends beyond the operation of the sprayer itself. Properly handle and dispose of any materials used in the spraying process, such as paint or chemicals. Follow local regulations and guidelines for the safe disposal of hazardous materials to minimize any potential harm to the environment or human health.

Cleaning and maintaining your sprayer

Regular cleaning and maintenance of your sprayer are essential for safe and efficient operation. Thoroughly clean the sprayer after each use to prevent clogs and maintain optimal performance. Follow the manufacturer’s instructions for cleaning and maintenance, and store the sprayer in a clean and dry place when not in use. By properly maintaining your sprayer, you can ensure its longevity and prevent any safety issues down the line.

Costs Associated With Sprayers

The initial cost of the sprayer

The initial cost of a sprayer can vary depending on the type and brand. Airless sprayers, with their higher power and efficiency, tend to be more expensive compared to HVLP or conventional sprayers. Consider your budget and project requirements when evaluating the initial cost of a sprayer.

Ongoing maintenance cost

In addition to the initial cost, it’s important to factor in the ongoing maintenance cost of the sprayer. This includes the cost of filters, replacement parts, and cleaning supplies. Research the maintenance requirements of the sprayer you are considering and estimate the long-term cost of keeping it in good working condition.

Cost for materials and accessories

Sprayers require specific materials and accessories for operation, such as paint, stain, or primer, as well as additional tips or nozzles. Consider the cost of these materials and accessories when budgeting for your sprayer purchase.

Potential cost for repairs

No matter how well-maintained a sprayer is, there is always the potential for repairs in the future. Research the availability and cost of replacement parts for the sprayer you are considering. Additionally, consider the warranty options offered by the manufacturer to provide added protection in case of any unforeseen repairs.

Understanding Sprayer Specifications

Horsepower and pressure

Horsepower and pressure are crucial specifications to consider when choosing a sprayer. Higher horsepower and pressure allow for faster application and better atomization of thicker coatings. Evaluate the horsepower and pressure requirements for your project to ensure that the sprayer you choose can handle the job efficiently.

Tip size and material compatibility

The tip size of a sprayer determines the spray pattern and flow rate. It’s important to choose the right tip size for the material you’ll be spraying to achieve optimal coverage and atomization. Check the sprayer’s specifications for the range of compatible tip sizes to match the specific material you’ll be using.

Flow rate and volume

The flow rate and volume refer to how much material the sprayer can deliver in a given amount of time. Different projects may require different flow rates, depending on the desired coverage and speed of application. Ensure that the sprayer’s flow rate and volume are suitable for the scale and requirements of your project.

Weight and ease of mobility

Consider the weight and ease of mobility of the sprayer, especially if you’ll be working on large-scale or outdoor projects. Heavier sprayers may be challenging to maneuver, while lighter sprayers may lack stability. Depending on your specific needs, choose a sprayer with a weight and design that is comfortable for you to handle for extended periods of time.

Benefits of Various Sprayer Types

Airless sprayers

Airless sprayers offer many benefits, including high efficiency and speed. They are capable of handling a wide range of materials and are suitable for large-scale projects. Airless sprayers also provide excellent coverage and minimal overspray, resulting in a uniform finish. They are an ideal choice for professionals and DIY enthusiasts looking to complete projects quickly and efficiently.

HVLP sprayers

HVLP sprayers excel in providing a smooth, professional finish with minimal overspray. They are perfect for detailed projects or surfaces that require precision. HVLP sprayers also tend to have lower operating pressures, making them safer and more comfortable to use for extended periods. With HVLP sprayers, you can achieve a high-quality finish with minimal material waste.

Air Assisted Airless sprayers

Air assisted airless sprayers combine the benefits of airless and HVLP sprayers. They offer the speed and efficiency of airless sprayers while providing the control and precision of HVLP sprayers. Air assisted airless sprayers are versatile and can handle a variety of materials, making them a popular choice for professionals who require flexibility and high-quality results.

Conventional sprayers

Conventional sprayers are suitable for smaller, more localized projects. They are easy to use and have a lower upfront cost compared to other sprayer types. Conventional sprayers are a great entry-level option for beginners or occasional users who need to tackle smaller tasks or touch-ups. However, keep in mind that they may produce more overspray and are not ideal for projects that require a high-quality professional finish.

Choosing a Sprayer Brand

Popular sprayer brands

When choosing a sprayer brand, it’s helpful to consider popular and reputable brands in the industry. Brands like Graco, Wagner, and Titan are well-known for their quality and reliability. Research different brands, read customer reviews, and seek recommendations from professionals to gauge the reputation and popularity of a particular brand.

Warranty and customer service

Evaluate the warranty and customer service offered by the sprayer brand. A solid warranty provides peace of mind and protection against any manufacturing defects or malfunctions. Additionally, responsive and helpful customer service can make a significant difference if you require assistance or have any concerns throughout your sprayer’s lifespan.

Reliability and longevity of products

Consider the reliability and longevity of products from the sprayer brand. Look for durable materials, solid construction, and positive feedback regarding the brand’s products. Long-lasting sprayers ensure that you get the most out of your investment and can rely on your sprayer for years to come.

User reviews and professional recommendations

User reviews and professional recommendations are valuable resources when choosing a sprayer and brand. Read reviews from other users who have firsthand experience with the sprayer you are considering. Additionally, seek recommendations from professionals who work in similar industries or have expertise in sprayer selection. Their insights can provide valuable guidance in making an informed decision.

Handling Sprayer Maintenance and Repairs

Routine maintenance for sprayers

Routine maintenance is essential to keep your sprayer in optimal condition. Follow the manufacturer’s guidelines for regular cleaning, filter replacements, and lubrication. Clean the sprayer after each use to prevent clogs and ensure smooth operation. Proper maintenance will extend the life of your sprayer and maintain its performance over time.

Common repair issues

Sprayers may encounter common repair issues, such as clogged nozzles, worn seals, or hose leaks. These issues can often be resolved by replacing the faulty parts or performing simple repairs. It’s crucial to familiarize yourself with the common repair issues specific to your sprayer and have access to replacement parts when needed.

Finding replacement parts

When a sprayer requires repairs, finding replacement parts quickly is crucial. Research and identify reliable sources for replacement parts for the sprayer brand you choose. This ensures that you can efficiently resolve any repair issues and minimize downtime during your projects.

When to replace your sprayer

No matter how well-maintained a sprayer is, there may come a time when it needs to be replaced. Factors such as extensive wear and tear, frequent repairs, or outdated technology may indicate the need for a new sprayer. Regularly assess the condition and performance of your sprayer and consider upgrading or replacing it to ensure consistent and efficient operation.

Educating Yourself on Sprayer Usage

Instruction manuals and user guides

Instruction manuals and user guides provided by the sprayer manufacturer are valuable resources for learning how to operate and maintain your sprayer. Carefully read and follow the instructions outlined in the manuals to ensure safe and proper usage.

Online tutorials

Online tutorials and videos are excellent sources of information for sprayer usage. Many manufacturers and professionals provide detailed tutorials on their websites or video-sharing platforms. These tutorials often cover various topics, including assembly, usage techniques, troubleshooting, and maintenance. Take advantage of these free resources to expand your knowledge and improve your spraying skills.

Professional training classes

For a more comprehensive understanding of sprayer usage, consider enrolling in professional training classes. These classes are often offered by industry experts or manufacturers and cover a wide range of topics related to sprayer operation, safety, and techniques. Professional training can enhance your skills and confidence when working with sprayers, ensuring better results and overall efficiency.

Best practices for sprayer use

Educate yourself on the best practices for sprayer use to optimize your spraying results. These practices may include recommendations on spray techniques, proper thinning of materials, maintaining the optimal spraying distance and speed, and maximizing the coverage. Applying the best practices will help you achieve professional-looking results and make the most of your sprayer.

In conclusion, choosing the right sprayer involves considering factors such as the type of sprayer, project needs, safety measures, costs, specifications, and brand reputation. By understanding the different types of sprayers and considering your project requirements, you can select the sprayer that best suits your needs. Remember to prioritize safety, perform routine maintenance, and educate yourself on sprayer usage to achieve optimal results. With the right sprayer and knowledge, you can tackle any spraying project with confidence and efficiency.

Upgrade Your Painting Game

Explore our Introduction To The Best Paint Sprayers guide to take your projects to the next level!