Introduction

Are you looking to revamp your engineered wood floors or furniture but unsure if it’s possible? Fear not! Painting engineered wood is not only possible but with the right tools, approach and these five expert tips, you can achieve stunning results.

In this blog post, we’ll dive into how to transform your space and add a touch of personalization by painting engineered hardwood floors and other surfaces with ease.

Key Takeaways – Can You Paint Engineered Wood? 💭

- Yes, you can paint engineered wood floors and furniture with stunning results.

- Proper surface preparation is crucial for achieving a long-lasting and professional-looking paint job on engineered wood surfaces.

- Using the right type of paint, applying multiple thin coats with ample drying time, and protecting the surface with a clear coat are essential tips to follow for the best results.

- Common pitfalls to avoid when painting engineered wood include skipping surface preparation steps, using the wrong type of paint or primer, applying too much paint at once, rushing through drying times, and failing to apply protective topcoats.

Table of Contents

Understanding Engineered Wood And Its Characteristics

Engineered wood is a popular choice for flooring and furniture due to its versatility, affordability, and appealing aesthetics. It is created by layering multiple thin sheets of hardwood together with an adhesive under pressure, resulting in a stable product that mimics the attractive appearance of solid wood.

One key characteristic of engineered wood is its resistance to moisture issues often associated with solid hardwoods. This makes it suitable for areas like kitchens or basements where fluctuations in temperature and humidity can cause traditional solid wood floors to warp or swell.

Another notable feature of engineered wood is its ability to be refinished if needed – although not as many times as solid hardwood considering its thinner top layer.

In summary, understanding these characteristics not only helps one appreciate why engineered woods are preferred by homeowners but also lays a foundation for discussing their potential transformation into stunning works of art through painting techniques which will be discussed next in this article series.

Can You Paint Engineered Wood?

Yes, you can! But to achieve stunning results, it’s essential to follow the right techniques and use the correct type of paint.

Surface Preparation

Proper surface preparation is crucial for achieving a long-lasting and professional-looking paint job on engineered wood. Before embarking on your painting project, begin by thoroughly cleaning the entire surface to remove any dirt, dust, or residue that could interfere with paint adhesion.

A simple solution of warm water and mild detergent works well for this purpose.

Next, lightly sand the surface using a 220-grit sandpaper in a circular motion to create an even texture and promote better binding between the existing finish and new paint layers.

Be cautious not to sand too aggressively as it may damage the thin veneer layer found in engineered wood products. Afterward, wipe away any residual dust with a tack cloth or damp rag.

Type Of Paint To Use

Selecting the right type of paint for your engineered wood project is crucial to achieving stunning results. In general, acrylic latex paint works well on this material as it adheres better and offers excellent durability.

It’s important to avoid oil-based paints when working with engineered wood because they may have difficulty adhering to the surface and can result in an uneven or peeling finish over time.

Additionally, using spray paint might not provide consistent coverage and could damage the thin veneer layer typical of engineered hardwood floors. When choosing a specific brand or color for your project, consider coordinating with other elements in your home such as furniture pieces and existing hardwood flooring, for a cohesive visual effect that enhances both aesthetics and functionality.

Techniques To Apply Paint

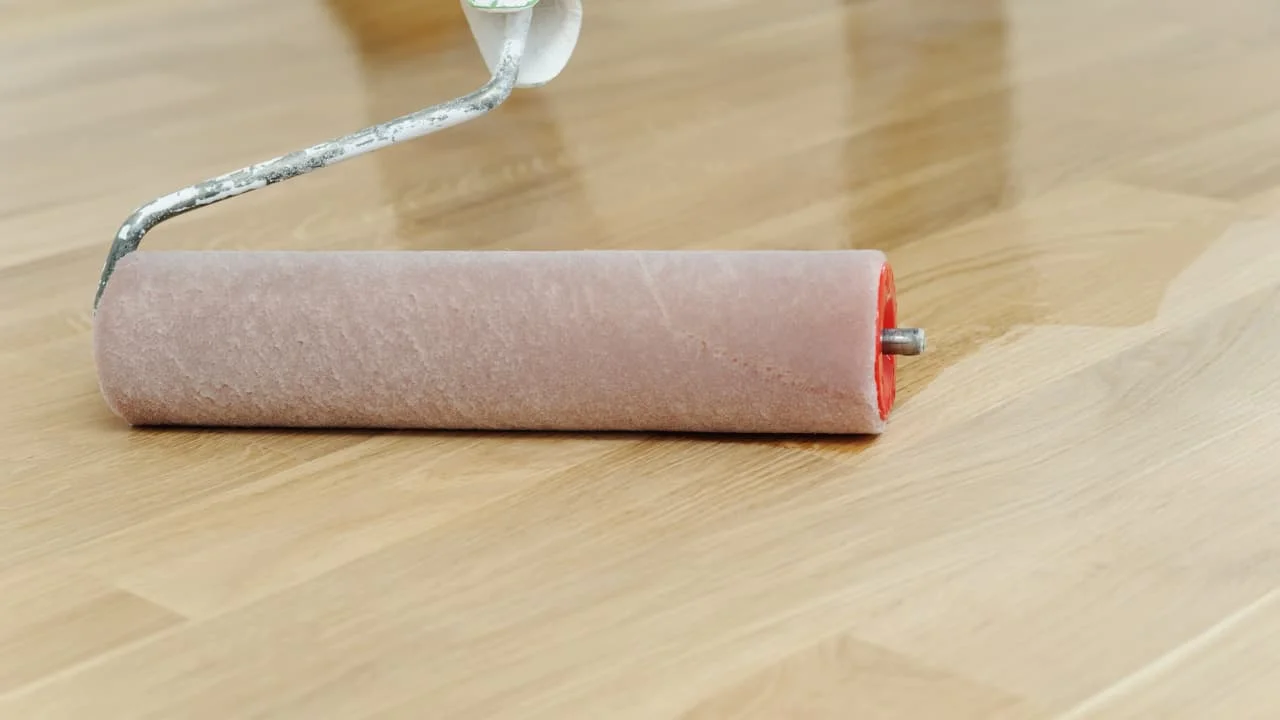

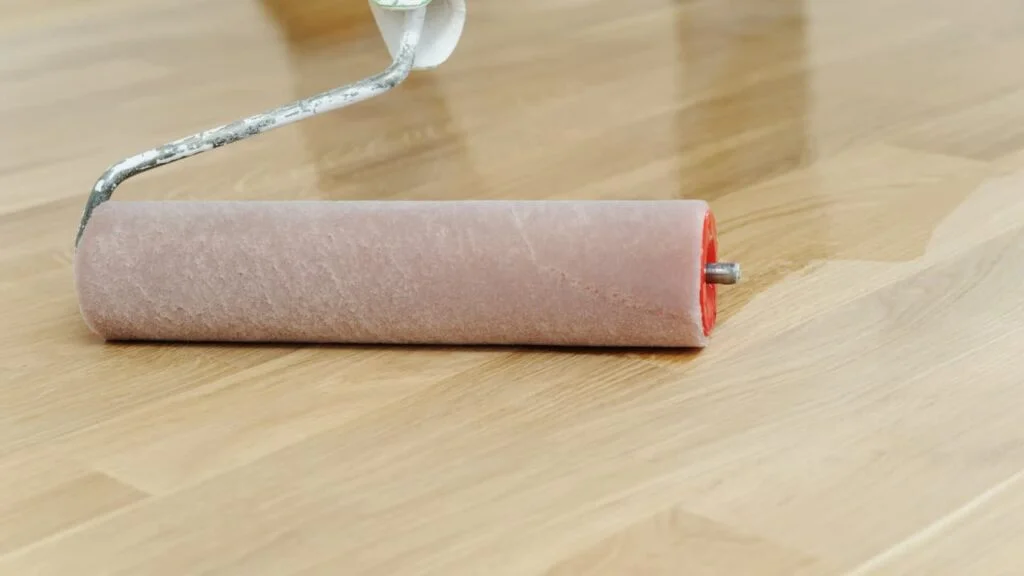

Applying paint to engineered wood requires some specific techniques to achieve a smooth and even finish. First, it’s essential to use a high-quality brush or roller that is appropriate for the type of paint you are using.

When applying the paint, use thin layers rather than trying to cover everything in one thick coat.

It’s also important to pay attention to the direction of your strokes when applying the paint. Start at one end of the piece and work your way across, using long, continuous strokes in a straight line.

Try not to go back over areas that you’ve already painted as this can cause streaks or smudging.

By following these simple techniques for applying paint, you’ll be able to achieve stunning results on your engineered wood furniture or flooring projects.

Tips For Painting Engineered Wood

To ensure stunning results when painting engineered wood, be sure to follow these tips for surface preparation, using the right type of paint and primer, applying multiple thin coats of paint with ample drying time between each coat, and protecting the surface with a clear coat.

Sanding The Surface

To achieve a high-quality paint finish on engineered wood surfaces, sanding the surface is crucial. Sanding creates tiny scratches on the surface that provide a better grip for the primer and paint to adhere to.

Use 220-grit sandpaper or an orbital sander with fine-grit sandpaper to gently scuff up the entire surface of the piece you want to paint, ensuring you get all areas evenly and thoroughly.

This removes any smoothness from the existing finish or any dirt or debris that may have accumulated over time, allowing for an even application of primer and paint. Make sure not to over sand, as this could damage the veneer layer of your engineered wood flooring or furniture piece.

Applying Primer

Before painting engineered wood, it’s crucial to apply the right primer. This step helps prepare the surface for paint and ensures that it adheres to real wood well and lasts longer.

Using a water-based primer is recommended since oil-based primers can cause yellowing over time. Apply one layer of primer using either a brush or a roller, making sure to cover all areas completely.

One important aspect to keep in mind when selecting your primer is compatibility with your chosen type of paint. For example, if you plan on using acrylic paint, then you will need an acrylic primer as well.

Using Multiple Thin Coats Of Paint

To achieve a stunning and long-lasting finish on your engineered wood surfaces, applying multiple thin coats of paint is crucial. Thick layers of paint can take longer to dry, leading to unsightly drips or peeling in the future.

When painting furniture or flooring made from engineered wood, start with one light coat and allow it to dry completely before applying additional layers.

This way, you can be sure that each layer adheres properly before adding another. It may take several coats to achieve the desired color and coverage but taking this patient approach will ultimately lead to a flawless finished product.

Allowing Ample Time For Drying

After applying the final coat of paint to your engineered wood, it’s essential to give it ample time to dry before moving any furniture or walking on the surface. Rushing the drying process can result in smudged surfaces and imperfections that may ruin your paint job.

It’s also important to keep in mind that curing times will vary based on factors like humidity levels and temperature. To ensure a stunning finish, check manufacturer guidelines for drying times specific to the type of paint you’re using on your engineered wood surface.

Applying A Protective Clear Coat

After completing your paint job, it’s vital to apply a protective clear coat to safeguard against chipping and wear. A clear topcoat provides an extra layer of protection, ensuring long-lasting durability for your painted surfaces.

When selecting a clear coat, consider the surface type and location where the item will be used. For example, if you’re painting engineered wood floors in high-traffic areas like kitchens or hallways, choose a durable finish that can withstand foot traffic.

Water-based polyurethane is ideal for interior projects because it dries quickly and has a low odor.

To get started on applying your protective finish, wait for your paint job to dry entirely before proceeding. Then use a clean brush or roller specifically designed for clear coats and apply one thin layer in even strokes across the entire surface area following manufacturer recommendations on drying times between each coat (usually 2-4 hours).

If you need more than one topcoat, remember to lightly sand with fine-grit sandpaper between layers to ensure smoothness.

Common Pitfalls To Avoid When Painting Engineered Wood

Skipping surface preparation steps, using the wrong type of paint or primer, applying too much paint at once, rushing the drying process, and not following curing times are all common pitfalls to avoid when painting engineered wood.

Skipping Surface Preparation Steps

Skipping surface preparation steps is a common mistake when painting engineered wood. However, it can lead to poor adhesion and an uneven paint job.

One important step is to give the entire surface a scuff or light sanding using 220-grit sandpaper to create a rough texture that promotes adhesion. Another crucial step is cleaning the surface thoroughly with soap and water or TSP (trisodium phosphate) to remove any dirt, dust, or grease that can hinder paint adherence.

For instance, failing to clean laminate furniture before painting can cause the painted finish to peel off easily in areas exposed to foot traffic. Similarly, skipping sanding on particle board coffee tables can result in the primer not sticking properly and creating an unattractive finished product.

Using The Wrong Type Of Paint Or Primer

Using the wrong type of paint or primer is one of the most common mistakes people make when painting engineered wood. It can happen when someone assumes that any paint or primer will work, rather than taking into account the specific needs of the surface being painted.

For example, oil-based paints and primers are not recommended for use on laminate furniture as they may cause it to bubble and peel over time. Instead, water-based paints and primers should be used to ensure a smooth finish that lasts.

Additionally, using a primer meant for metal on wood surfaces can inhibit adhesion and lead to chipping or peeling down the road.

Applying Too Much Paint At Once

One of the most common painting mistakes is applying too much paint at once. It can be tempting to use a heavy hand in hopes of finishing the job quickly, but this approach often leads to unsightly drips and uneven surfaces.

Instead, it’s best to apply multiple thin coats of paint, allowing each one to dry completely before moving on to the next.

To illustrate this point, consider an example of someone painting a coffee table. If they were to load up their paintbrush with too much paint and slap it onto the tabletop all at once, they would likely end up with thick globs that take forever to dry and look unattractive.

Rushing The Drying Process

One of the most common mistakes people make when painting engineered wood is rushing the drying process. It can be tempting to apply multiple coats of paint quickly or move furniture back into a newly painted room, but this can lead to serious problems.

Rushing the drying process can cause paint to peel or crack, ruining all your hard work.

For example, giving your floors ample time to dry between coats is crucial for ensuring that they last longer and maintain their good looks. Applying a protective topcoat on freshly painted engineered wood furniture before it’s fully cured could result in an uneven finish that will need touch-ups in no time.

Not Following Curing Times

Skipping or rushing the drying and curing process can result in a poorly executed paint job on engineered wood. It’s important to follow the manufacturer’s recommended cure time as it allows the paint to fully bond with the surface, which increases its durability and longevity.

Rushing this process could lead to chipping, peeling, or flaking of paint over time.

For example, not allowing ample time for the first coat of paint to dry before applying a second coat can cause issues when trying to achieve an even finish. Additionally, if protective topcoats are applied too soon after painting without ensuring that each layer is completely dry first, there may be long-term adhesion problems.

Care And Maintenance Of Painted Engineered Wood

Regular cleaning and dusting, as well as avoiding harsh chemicals and abrasives, are important for the care and maintenance of painted engineered wood. Keep your surfaces looking stunningly new by touching up any chips or scratches that may occur over time.

Regular Cleaning And Dusting

To keep painted engineered wood looking its best, regular cleaning and dusting is crucial. Dust and debris can accumulate on the surface of the wood and cause scratches or other damage over time.

Using a soft cloth or static duster, gently wipe down the surface of furniture or floors to remove any dirt or dust. For tougher stains or spills, use a mild soap solution with warm water and a soft sponge to gently clean away dirt.

Remember to touch up any chips or scratches as soon as they occur to prevent further damage.

Avoiding Harsh Chemicals And Abrasives

When caring for painted engineered wood, it is important to avoid using harsh chemicals and abrasives, as they can damage the finish. Instead, use a soft cloth or sponge with mild soap and water to wipe down the surface.

If your painted engineered wood surface has sustained some minor scratches or chips, touch them up with a small brush and matching paint. For more significant damage that requires re-painting the whole area, make sure to follow proper surface preparation techniques before applying new paint coats.

Touching Up Any Chips Or Scratches

If you paint engineered wood, it’s important to continue maintaining the surface after completion. Regular cleaning and dusting are essential for keeping your finished project looking its best.

Avoid harsh chemicals and abrasives that can damage the painted surface. Additionally, touching up any chips or scratches will prevent further damage from occurring.

One smart tip is to use a toothpick or small brush to carefully apply touch-up paint only where needed, instead of repainting larger areas unnecessarily. This allows for seamless repairs without having to redo the entire surface.

Advantages Of Painting Engineered Wood

Painting engineered wood offers numerous benefits, including customization options to match your color scheme and protect the surface from potential damage.

Customization Options

Painting engineered wood surfaces offers a host of customization options to enhance the aesthetics of your space. You can choose any color scheme that fits your personal style and complements the existing decor.

With paint, you can create furniture or revamp an old piece with a modern flair. The possibilities are endless. Furthermore, customizing your floors by painting them is an affordable alternative to solid wood flooring without sacrificing durability or quality.

Cost-Effective Alternative To Solid Wood

One major advantage of painting engineered wood is that it is a cost-effective alternative to solid wood. Solid wood can be expensive, especially when you are looking for furniture or flooring options with unique finishes or designs.

Engineered wood, on the other hand, allows homeowners to achieve similar looks and styles as solid wood at a fraction of the cost. Additionally, because it is made up of multiple layers of a wood composite material rather than one solid piece, engineered wood resists warping and cracking better than traditional hardwoods.

Protecting The Surface From Damage

To protect the newly painted surface of your engineered wood furniture or flooring, it is essential to apply a protective topcoat. This clear coat will not only add an extra layer of protection against scratches and wear but will also enhance the durability and longevity of your paint job.

You can choose between water-based polyurethane or oil-based varnish for this purpose. Water-based finishes are eco-friendly, dry quickly, and provide a crystal-clear finish without yellowing over time.

It’s important to note that applying multiple thin coats is much better than applying one thick coat since thicker coatings tend to crack over time due to foot traffic or temperature changes.

Before applying the protective finish, make sure that you have allowed ample time for drying after painting (around 24-48 hours) as well as between each coat application (around 2-4 hours).

Increased Durability

Painting engineered wood can increase its durability, protecting it from scratches and other surface damage. This is particularly helpful for high-traffic areas like floors or furniture that sees a lot of use.

In addition, painting can help extend the life of older pieces by covering up imperfections and wear marks. It’s an easy way to breathe new life into an old piece without having to replace it altogether.

Enhancing Aesthetics

Painting engineered wood not only serves as a way to protect the surface but also provides an opportunity to enhance its aesthetics. With the wide range of color options available, homeowners can create a custom look that complements their decor and personal style.

Additionally, painting can be used to breathe new life into old or worn furniture pieces. For example, a tired-looking coffee table could be transformed with a fresh coat of paint in a bold hue or trendy design.

Conclusion

In conclusion, painting engineered wood is a great way to refresh and update the look of your floors or furniture. With these five tips – from surface preparation to using the right type of paint and techniques – you can achieve stunning results that will enhance the beauty of any space.

Remember to avoid common pitfalls such as rushing through drying times and failing to apply protective topcoats. Regular maintenance will ensure your freshly painted surfaces last for years to come, with touch-ups as needed.

FAQs:

Can all types of engineered wood be painted?

Not all types of engineered wood are suitable for painting. It is important to check the manufacturer’s instructions and consult with a professional before attempting to paint your material in order to avoid damage or unsatisfactory results.

What steps should I take before painting my engineered wood?

Before painting any surface, ensure that it is thoroughly cleaned and free from debris, dust, or grease. Sanding the surface gently can also improve adhesion between the paint and the material.

Which type of paint is best suited for engineered wood?

Water-based acrylic paints are generally recommended as they provide a durable finish and do not emit harmful fumes like oil-based paints might. Choosing a high-quality primer can also help ensure better coverage and durability over time.

4. Should I use a sealer after painting my engineered wood?

A clear coat sealer applied after painting can help protect against wear and tear, stains, or fading due to exposure to sunlight over time, but it may not be necessary depending on where the item will be used (indoors vs outdoors) or how much traffic it will endure.

Are there any special techniques when painting engineered wood versus solid hardwood?

Engineered Wood has an outer layer that determines its color & texture – so you need to consider these factors while selecting your paint colors accordingly whereas with Solid Hardwood it’s just about taking care of natural grains & patterns